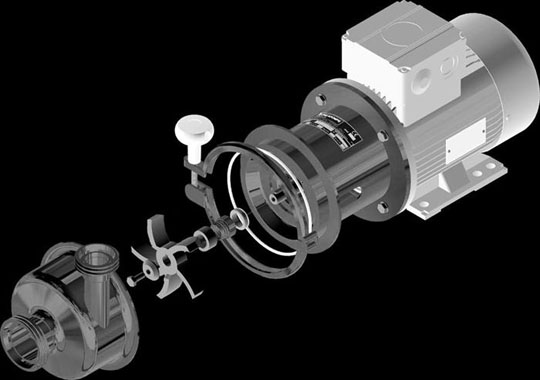

It is mainly used to transfer thick liquid and/or liquid with solid particles in suspension (diameter not too big). The backward rotor reduces to a minimum the contact of the substance with the rotor. That is, the liquid is pumped by “dragging”. This avoids that the impeller gets blocked with the particles in suspension or with filaments. It is suitable for the Pulp Industry, for the Dyeing Industry as well as for the Agricultural-Food Industry.

WHY TGA?

Because it is a versatile and economical pump. However, it is not possible to pump solid particles in suspension with a medium/big diameter.

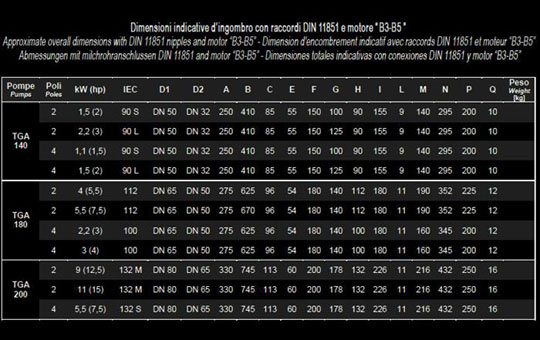

TECHNICAL FEATURES:

• Material: AISI 304/316

• Impeller: Open 5 blades

Ø min 115 - Ømax 195 (mm)

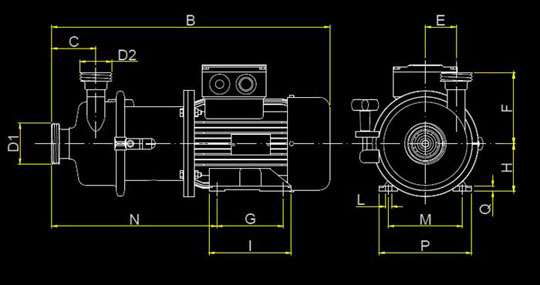

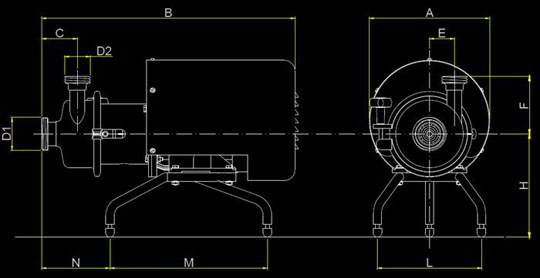

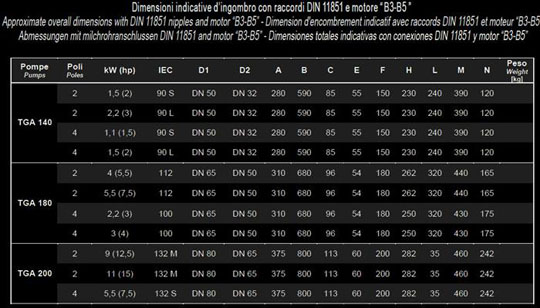

• Nipples: DIN 11851 (standard), GAS, SMS, etc. (on request)

• Motor: 2-4 poles, IEC B5 flange, IP55, Aluminium

PERFORMANCE:

Pulp, Dyeing, Food Industries

• Capacity up to 90 m³/h (330 Imp.g.p.m)

• Total head up to 40m (130 feet)

• Max Ø solid particles in suspension 20 mm.

• Max. fluid viscosity 1000 cP